Steel silos are important engineering structures that enable the storage of various materials such as grain, cement, sand, coal, and more.

Depending on their purpose and location, steel silos can be found in a wide range of sizes, capacities, and types.

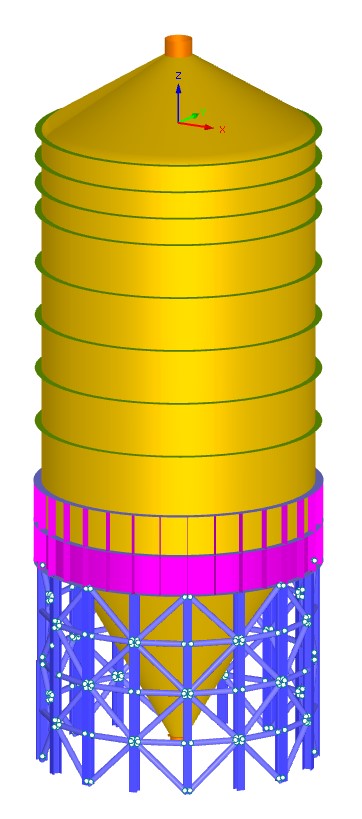

Steel silos can either rest directly on a reinforced concrete slab on the ground or be elevated on supporting steel profiles if complete emptying of the silo and the natural flow of the material under gravity is required. In such cases, conical hoppers are added beneath the main body to facilitate the desired flow rate and pattern.

The main body of the silo can be constructed from flat steel plates welded or bolted together, or it can be made from trapezoidal steel sheets.

Trapezoidal sheets are only capable of resisting the tensile forces caused by the pressure of the stored material on the silo walls. Therefore, additional cold-formed light steel structural profiles are required to handle other forces.

Especially large-volume elevated steel silos are highly complex structures. As a result, even in 2020, they remain one of the types of structures most prone to damage and collapse.

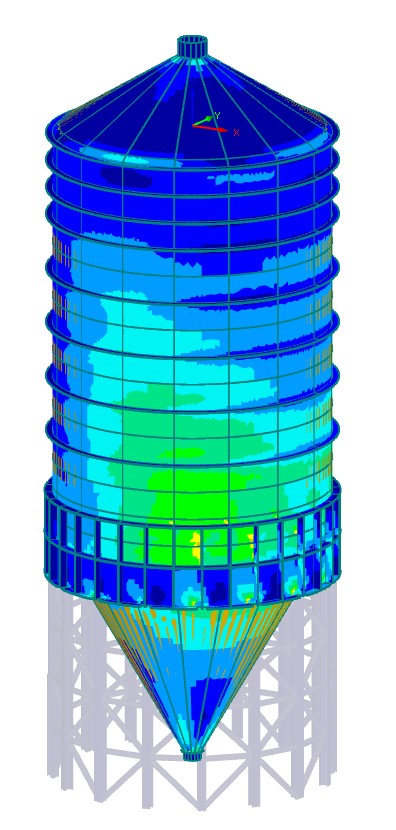

Since the unit weight of the stored material and the forces it exerts on the walls deviate from characteristic values due to factors like temperature, moisture, compaction, etc., calculations are performed for both upper and lower limits. During filling and emptying, these forces continuously change, leading to dynamic effects. Dynamic effects are accounted for using coefficients. The flow type inside the steel silo is determined based on the geometric properties of the conical hopper. Depending on this flow type, stresses in the main body and conical hopper are calculated. Tensile, compressive, and shear stresses continuously vary along the width and height of the silo. Tensile stresses force the material to yield, while compressive stresses lead to stability issues before yielding occurs. Imperfections in the silo walls significantly affect stability problems. These imperfections must also be included in calculations, even if they fall within the tolerances specified by standards. Additionally, boundary conditions are crucial. The distribution and magnitude of these stresses change depending on the rigidity of the connection point between the supporting system and the main body of the steel silo or the design of the silo roof. Even a one-degree slope in the ground can disrupt the entire balance of the structure.

Like many other structures, steel silos are exposed to effects such as snow, wind, earthquakes, temperature, corrosion, etc., and must be designed accordingly. When the silo is empty, the stored material’s effect on reducing wind pressure on the silo walls is absent, making buckling more likely.

Large-volume silos are heavy structures due to the mass of the stored material. The supporting system, along with the steel silo walls, can carry loads dozens of times their own weight.

Since current technology does not allow silos to detect earthquakes in advance and empty their contents within seconds, the supporting system must withstand the large horizontal and vertical forces caused by these heavy masses. On top of this, because the material inside the steel silo is fluid-like, it impacts the silo walls during an earthquake, creating additional stresses on the walls.