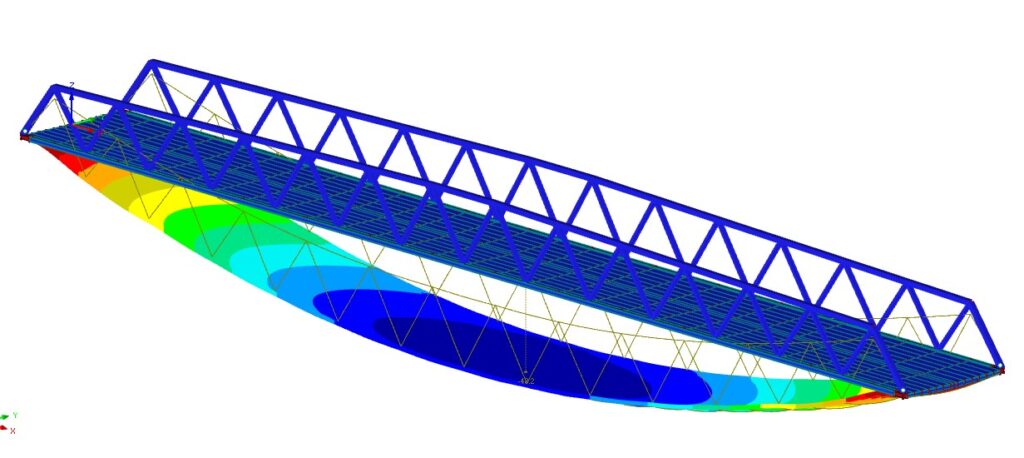

As bridge spans increase, the self-weight of the structure begins to dominate the design. Every millimeter of asphalt or deck concrete thickness, as well as the weight of safety barriers and bridge lighting, can influence the bridge sections.

Therefore, for long-span bridges, concrete—which has a much higher weight/performance ratio compared to steel—is avoided in deck sections. Concrete can crack, creep, and shrink. Considering the lifespan of long-span bridges, these concrete components may need to be replaced or renewed several times, leading to significant costs and time.

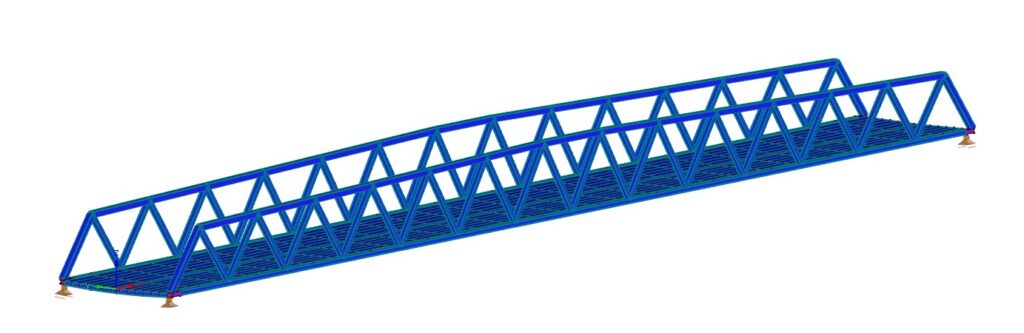

In 1948, German engineer Dr. Cornelis, who worked at MAN, patented the orthotropic deck. In an orthotropic deck, vehicle or pedestrian loads are transferred in the longitudinal direction of the bridge by steel plates reinforced with welded plates or profiles to increase rigidity. These loads are then carried in the transverse direction by secondary beams placed at regular intervals. The same plate can either work integrally with the main and secondary beams or function independently.

In pedestrian bridges, the steel plate can be covered with a protective layer just a few millimeters thick, while for heavy vehicle traffic, an asphalt layer is required.

With the appropriate paint and protection systems applied to the steel plates, a service life of up to 100 years can be achieved.

Since the self-weight of the deck is reduced, the bridge piers, foundations, and, if present, supporting cables can be designed more economically.